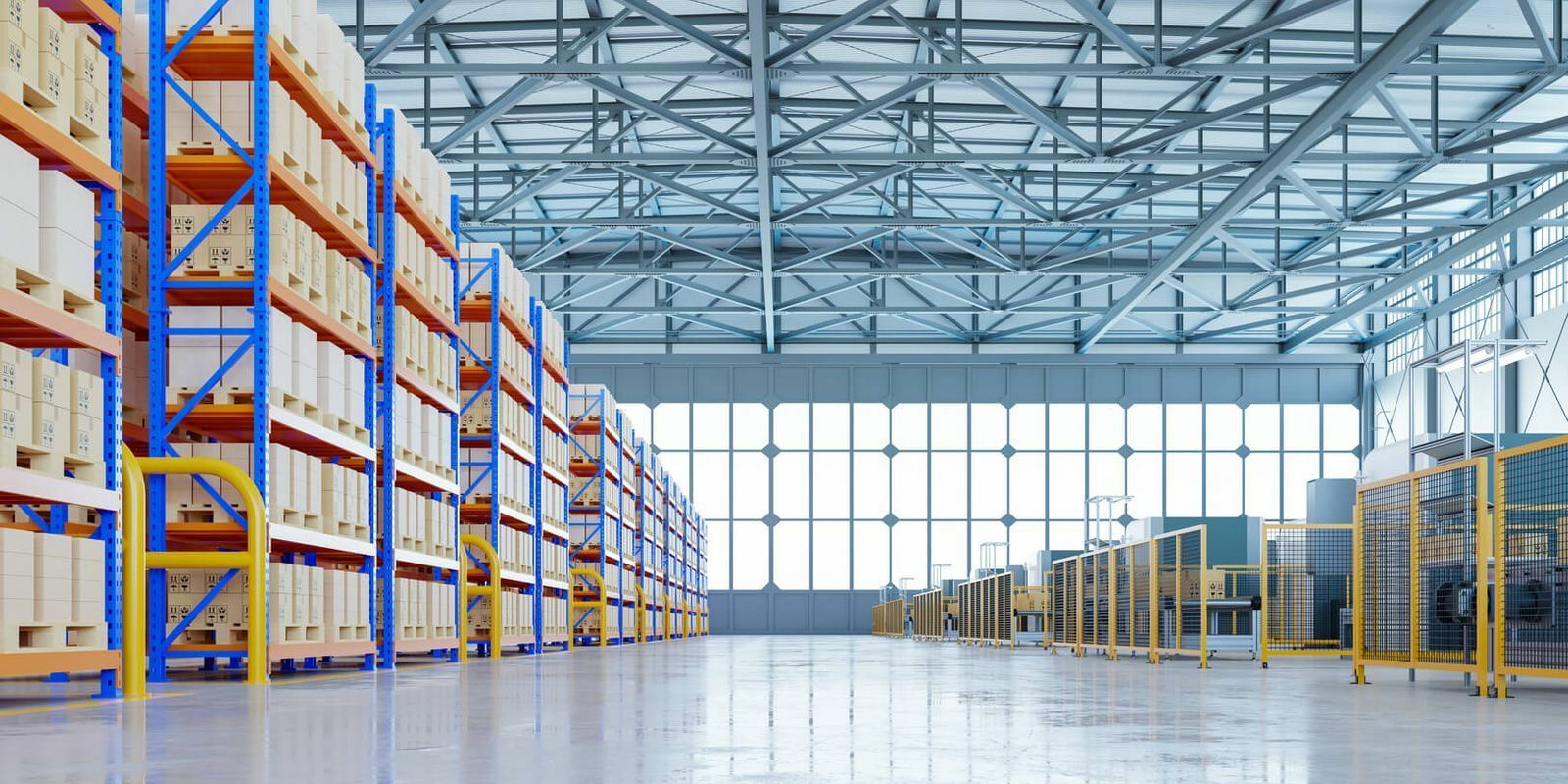

Warehousing refers to the process of storing goods or products in a designated location, known as a warehouse. It involves the systematic arrangement, organization, and management of inventory to ensure its availability whenever needed. Warehouses act as distribution centers, serving as intermediaries between manufacturers, suppliers, and customers.

Public warehousing involves leasing storage space in a warehouse facility owned by a third-party logistics provider (3PL). This solution is suitable for businesses with fluctuating storage needs or those seeking cost-effective storage options. Public warehouses offer flexible storage solutions, shared resources, and additional services such as packaging, labelling, and transportation.

Private warehousing involves businesses owning and operating their warehouses. This solution is suitable for large-scale enterprises that require dedicated storage facilities to manage their unique inventory needs. Private warehouses offer greater control over operations, customization options, and the ability to align warehousing strategies with overall business objectives.

Contract warehousing is a hybrid solution that combines elements of both public and private warehousing. In this arrangement, businesses enter into a contractual agreement with a 3PL to establish a dedicated storage facility tailored to their specific requirements. Contract warehousing provides businesses with the benefits of private warehousing without the need for significant capital investments.

Distribution centers are large-scale facilities designed to receive, store, and ship products to various locations. They serve as central hubs for inventory management and order processing. Distribution centers are strategically located to optimize transportation routes and reduce delivery time, making them essential for businesses with extensive distribution networks.

ALL WAREHOUSING OPERATIONS

We offer comprehensive storage and fulfillment services,

A warehouse management system (WMS) is defined as software designed to manage the movement of inventory to know where final products and goods are at any time to fulfill orders. A warehouse management system can be standalone software or part of an enterprise resource planning (ERP) system working with other integrated modules such as accounting, order management, inventory management, MRP, customer relationship management (CRM), and more using one central system and data source.

With WMS software in place, running a warehouse and distribution center is much easier as it provides step-by-step guidance and verifies processes are being done correctly at each step. It can take away human error from a paper-based approach to improve efficiency, increase the speed of shipping and delivery, and improve the quality of customer service. It provides immediate insight into what is happening within the warehouse and historical information based on tracked data to understand trends and demand. Companies using a warehouse management system can be more competitive, provide a better customer experience, keep up with constantly changing demand, and optimize their supply chain.

Streamline inbound and outbound processes, automate manual and paper-based processes such as inventory tracking and labeling, create more efficient warehouse routes, improve warehouse layout, and prioritize goals for more efficient operations.

Lower labor costs by speeding time to find items, reduce waste of premium floor space with a better layout, automate processes for fewer errors, and increase inventory visibility to reduce storage needs.

Greater customer satisfaction from reduced mistakes, faster delivery times, and improved order status, and better vendor relations from quicker delivery approvals, and increased supply orders.

Improved efficiency and visibility in the warehouse also help to optimize the supply chain with faster processes and better demand planning.

Real-time data, status, and tracking of inventory through barcoding, serial numbers, and RFID tagging to track its movement throughout the warehouse to keep stock at optimal levels.

Labor forecasting and KPIs to identify when staff is needed and how to optimize staffing and shifts to more efficiently create schedules and assign tasks.

With automated processes, increased data and visibility, and more efficient task assignments, employees can provide more value and feel more empowered, increasing employee satisfaction and retention.

Systematizing your warehouse management processes provides greater accountability, eliminates unauthorized access to critical data, and establishes an audit trail.

Visibility and data help identify bottlenecks and improvements. For example, WMS software can run “what if” scenarios to determine how changes will impact operations.